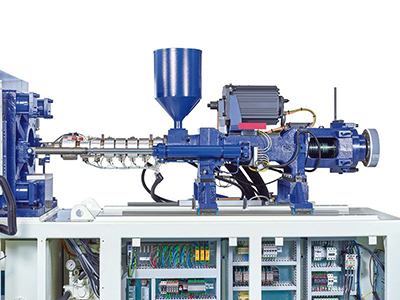

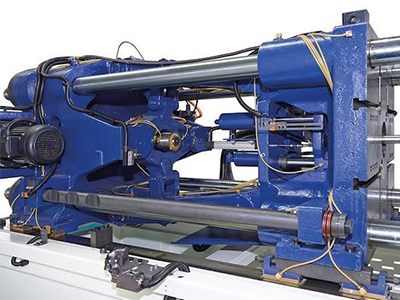

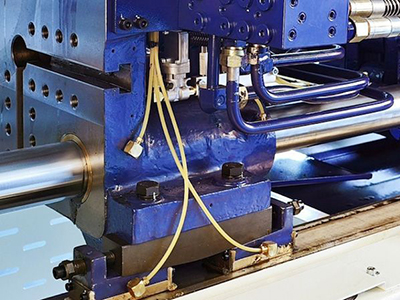

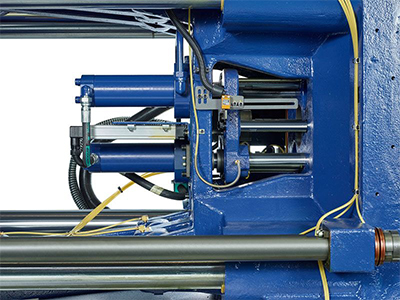

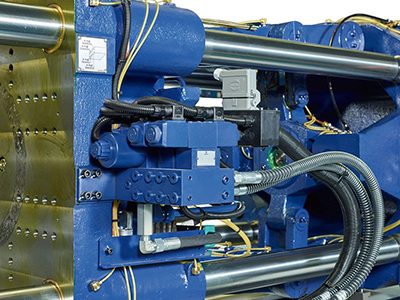

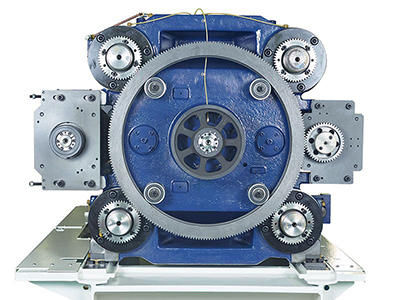

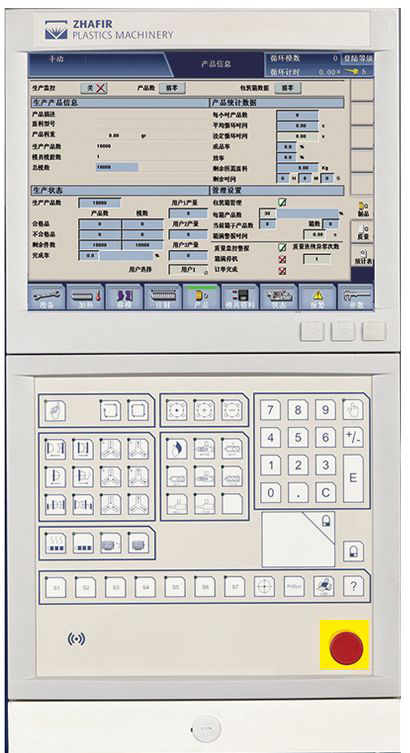

Discover new ways but on a familiar territory by using the advantages of electric injection-molding technology in areas traditionally associated with hydraulic machines. The Zeres Series, identical in construction to the all-electric Venus II Series, offers an integrated hydraulic system. Main movements like mold and injection are all-electric. Side axis like nozzle movement, cores and ejector are hydraulic.

In this way, the Zeres gives the processor not only the wide electric range of applications but at the same time also more production efficiency because of energy savings in the double-digit percentage range. Currently, the Zeres Series is available in clamping forces from 400 to 13,800 kN.