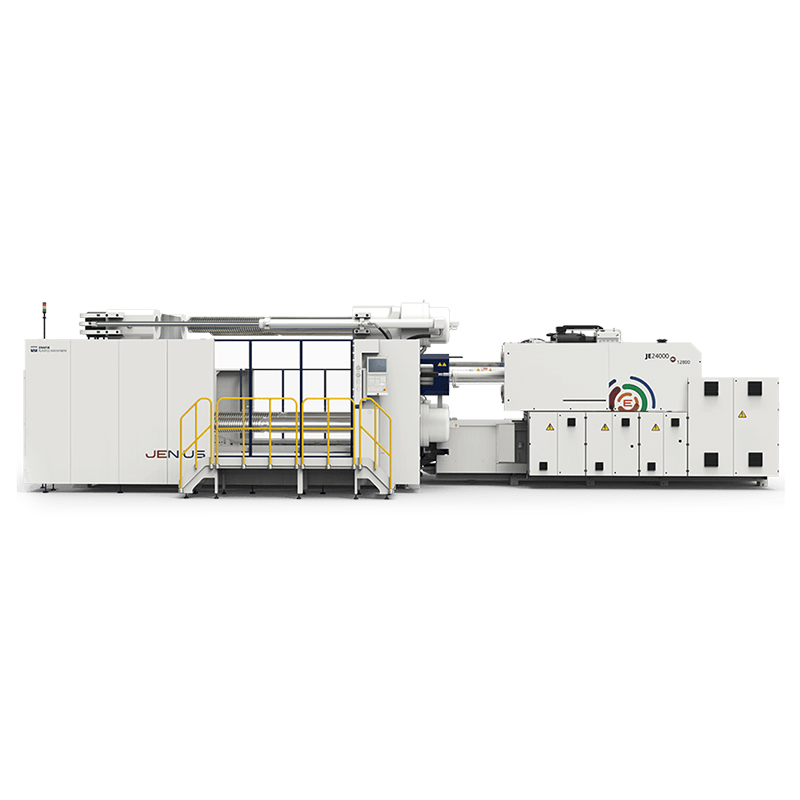

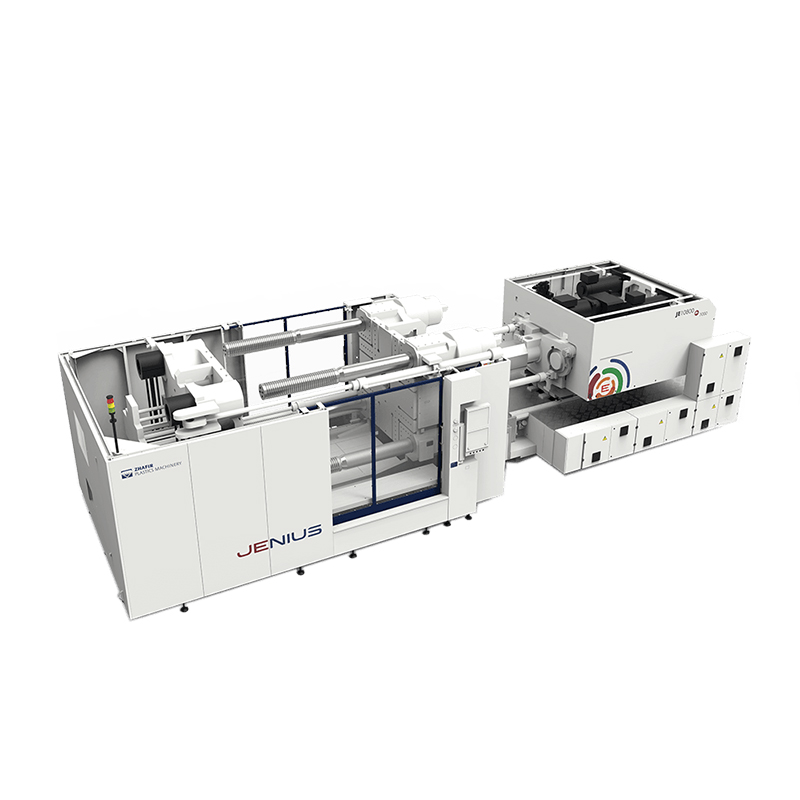

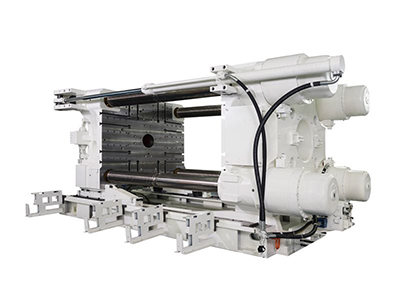

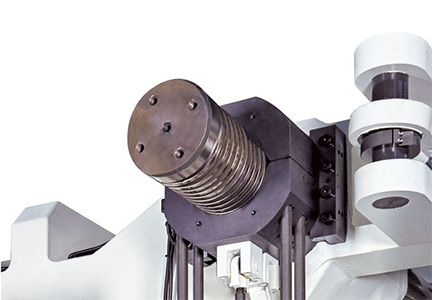

The Zhafir Jenius Series (JE) is an innovative hybrid machine concept which combines the electric drive technology and the two-platen servo hydraulic system. Using an innovative modular concept, the fully electric solution and the servo drive system can be combined in a highly efficient way, while their respective benefits are being retained.

It is benefited from our profound application experience from customers and pay attention to the development tendency of medium and large injection molding technologies. JE has been developed to address the specific quality requirements for industries such as white goods and automotive. With excellent stability, higher efficiency and faster investment return, JE is an ideal choice for the customers in the industry.